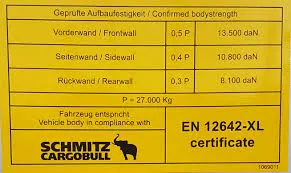

Wall support example

This is the posting number 8 in a series of cargo securing advice and useful hints. These are meant for people who think economically. They do not like to waste time, muscle power, risk their health or pay fines.

Now we have gone through the need for lashing, the support available, and the friction. You might now wonder if you have to lash at all when you have a trailer done according to XL-code? An example: a trailer might have 27 tons payload like in the picture of the sticker that has to be found outside the front headboard. Then the front headboard will support your cargo with 13.5 tons, the sides with 10.8 tons and the back doors with 8.1 tons.

Additionally, the friction might give you some support, depending on the friction coefficient. Let’s say you have the cargo on plastic pallets on plywood floor, then the friction is a very low µ=0.2 and if your cargo weighs for example 26 tons, then you have the friction force in your favor of only 5.2 tons in all directions.

You still have to secure it because the requirement is 27×0.8=21.6 tons forward and you have only 13.5+5.2=18.7 tons secured. But for the other directions you get it easier: To the side the requirement is 27×0.5=13,5 tons and you have 10.8+5.2=16.0 tons and if there is a tipping risk the requirement is 27×0.6=16.2 tons and you have 16.0 tons, not quite OK. Required protection against backwards movement is 27×0.5=13.5 tons and you have 8.1+5.2=13.3; not quite enough here either.

Note: All of this is true ONLY if you have a uniform cargo that fills ¾ of the height and almost all of the floor space.

Drive safely,

Cargo Lashing Expert.